Efficient Protective Packaging

Paper cushion offers lightweight yet strong protection. It securely wraps fragile items, preventing movement and reducing breakage during transit.

Give your items a soft landing with our paper-based cushion filler. It protects fragile goods without a shred of plastic, keeping packaging guilt-free.

Choose from our library of custom paper cushion curated from popular demand.

Apply UV-curing coating to local areas of printed matter to create a special effect of bright protrusions, thus achieving precise highlighting of the visual focus.

A layer of transparent plastic film is covered on the surface of the paper, which is divided into glossy film and matte film, which can enhance the waterproof and wear resistance and improve the overall texture.

Through ultraviolet light instant curing technology, a transparent protective layer is formed on the surface of the material, which has both high gloss and scratch resistance, extending the service life of the product.

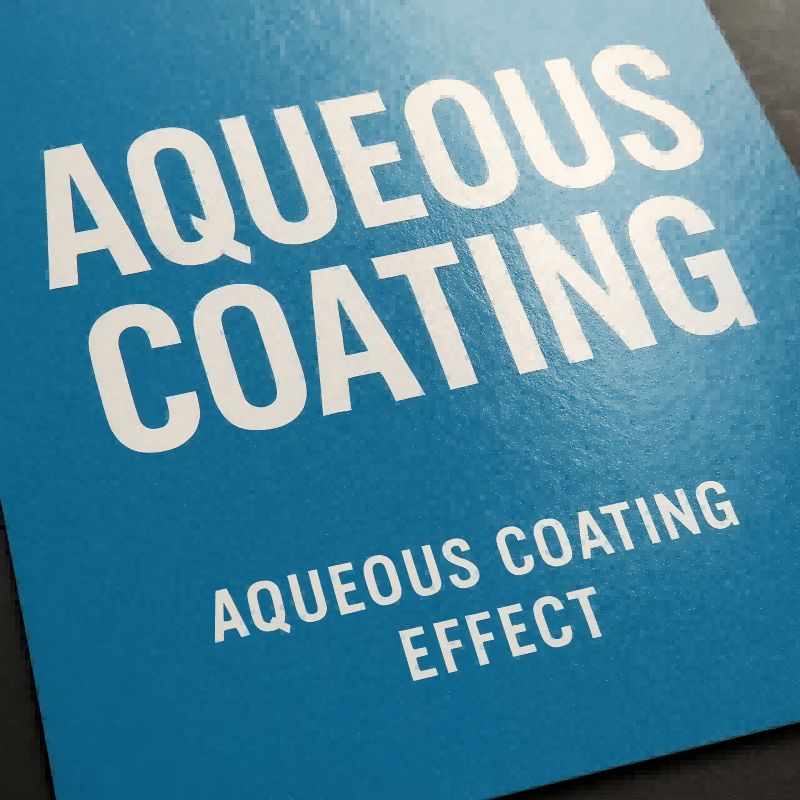

Environmentally friendly, water-based paint that is safe and non-toxic and can give materials a soft matte or high-gloss surface effect.

It is made of corrugated core paper and surface paper, has good cushioning and shock resistance, and is an economical material commonly used in the packaging field.

Made of wood pulp, it has a tough and fold-resistant texture, and a rustic and natural feel, making it suitable for environmentally friendly packaging and retro style design.

The surface is coated with gold or silver paint or covered with metal film, which has a dazzling luster and is often used in gift boxes, greeting cards and other scenes that show luxurious texture.

Produced using special techniques or raw materials, it has unique texture, rich colors, and delicate texture, providing more creative possibilities for design.

The paper is white, smooth, crisp and thick, and has strong adaptability to printing. It is a commonly used basic material for making business cards, leaflets, packaging boxes, etc.

By high-temperature embossing of metal foil, the paper is given a striking metallic luster, enhancing its visual quality.

Using molds to print out a three-dimensional relief effect gives flat materials a vivid sense of touch and layering, enhancing visual tension.

View paper cushion solutions for different products and fields and get artistic inspiration.

Paper cushion offers lightweight yet strong protection. It securely wraps fragile items, preventing movement and reducing breakage during transit.

Made from recyclable paper, paper cushion is a sustainable replacement for plastic bubble wrap. It supports businesses committed to minimizing environmental impact.

From ceramics to electronics, paper cushion adapts to diverse packaging needs. It’s easy to use, space-saving, and perfect for protecting delicate goods.

Ecofold packaging helps your brand grow

Usually, the most common materials for the production of folding boxes are white cardboard and kraft paper. The weight requirement is determined by the actual weight of the packaged product and the size of the box. Generally, 300gsm or 350gsm paper is used. For higher requirements, we will use 400gsm, or achieve a higher weight such as 600/700gsm hardness by mounting 300gsm and 350gsm.

Usually we recommend customers to use lamination to ensure that the packaging box will not crack when folded. Paper is made of various plant fibers, etc. Folding multiple times or in a dry environment will cause the paper to crack when folding the box. If a layer of tough plastic film is covered on the paper, it will prevent the paper from cracking.

Generally, we can produce most common market – sized folding boxes. Please send the dimensions of your desired folding box (length: XX, width: XX, height: XX) to our packaging experts. We guarantee a prompt response within 24 hours.

Before printing, we will professionally process the design file you provide. Once the file is processed, we will send it back to you for confirmation. You can propose size adjustments at the file – confirmation stage, and there is no limit to the adjustment range.

We use environmentally – friendly UV ink for printing. Due to the rapid – curing nature of UV ink, the printed colors are more vivid. Additionally, we can perform complex processes such as hot stamping, embossing, and local UV coating.

Absolutely. Our advanced printing presses are capable of printing extremely fine patterns with high precision. Moreover, our color management system ensures excellent color reproduction, even for complex gradient – colored designs.

We attach great importance to color stability. Under normal circumstances, the color stability of folding boxes printed in different batches is very high, and there will be no obvious batch color difference. This is mainly based on the following guarantees:

*We use advanced printing equipment, which has high – precision color control and calibration systems to ensure the color accuracy of each print.

*We have established a complete color management system. Starting from the design files provided by the customer, we will convert and calibrate the color space to ensure that the color of the design draft can be accurately restored in our printing system.

*We have a strict quality inspection process. After each batch of folding boxes is printed, there will be a dedicated quality inspector to carefully check the color, pattern, etc. of the product. If there is a color problem, it will be immediately arranged for reprinting to ensure that the products delivered to customers can meet high – quality color standards.

We have a wide range of folding box structures, including tuck – end boxes, snap – lock boxes, auto – bottom boxes, and special – designed folding boxes. Based on your product characteristics, such as size, shape, fragility, and your sales methods (e.g., retail display, shipping requirements), we can recommend the most suitable structure for you.

When we produce and ship the folding boxes, they are in a flat – packed state. You can easily fold them to complete the packaging. Under normal usage conditions (i.e., without violent folding), the boxes are highly durable and can be reused.

Normally, our delivery time is 12-15 days after receiving the deposit and confirming the printing documents.

Usually our delivery is by sea. If it is a small batch order, it can be transported by air, rail, etc. This is very flexible.

The freight is generally borne by the customer, but we will provide the most reasonable transportation method within the customer’s budget.

We are a printing factory. For the design of printed patterns, we usually cooperate with domestic professional packaging design companies.

But we have very professional opinions on the subsequent process design improvements and box structural design improvements of the design draft. We can help customers quickly promote the implementation of packaging projects.

Of course! Our factory welcomes customers to visit the site. This can help customers more intuitively view the professionalism of our factory and the production status of the order.

We do not have a minimum order quantity for small batch customization. You can also make one or ten samples. If for bulk production, our minimum order quantity is 1000pcs.

The quotation provided does not include the design fee. Our price is the ex – factory price of the packaging box. If you require design services, we can provide you with a separate quotation from our design partners.

Contact Info.