Showcase Products with Style

Display boxes are designed to attract attention at first glance. Their eye-catching presentation increases product visibility, encouraging impulse purchases at the point of sale.

Make your product the center of attention with our eco-friendly display boxes. They captivate customers on the shelf while staying kind to the planet.

Choose from our library of custom display box curated from popular demand.

Apply UV-curing coating to local areas of printed matter to create a special effect of bright protrusions, thus achieving precise highlighting of the visual focus.

A layer of transparent plastic film is covered on the surface of the paper, which is divided into glossy film and matte film, which can enhance the waterproof and wear resistance and improve the overall texture.

Through ultraviolet light instant curing technology, a transparent protective layer is formed on the surface of the material, which has both high gloss and scratch resistance, extending the service life of the product.

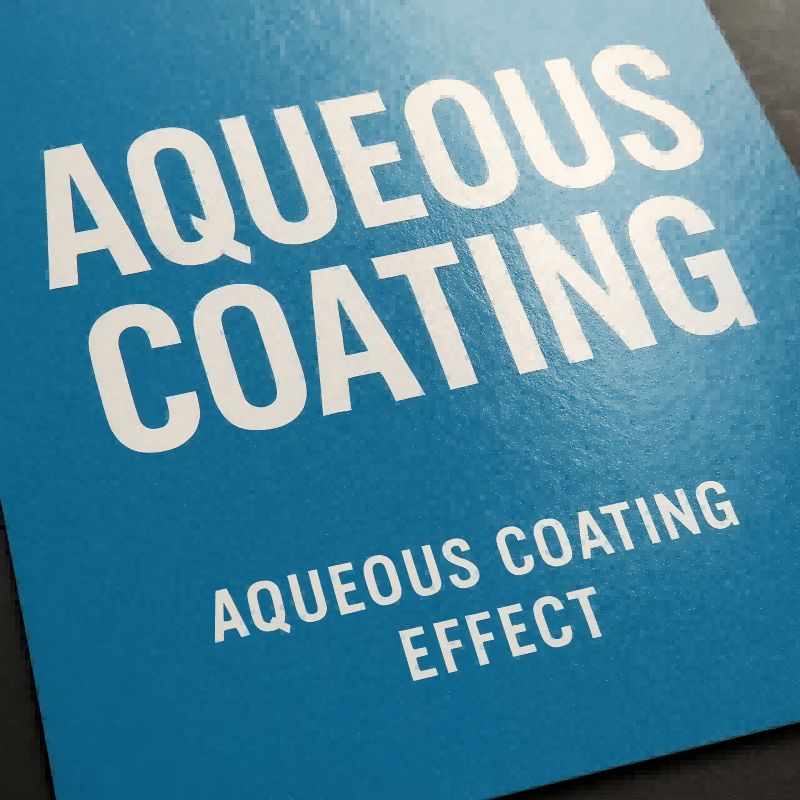

Environmentally friendly, water-based paint that is safe and non-toxic and can give materials a soft matte or high-gloss surface effect.

It is made of corrugated core paper and surface paper, has good cushioning and shock resistance, and is an economical material commonly used in the packaging field.

Made of wood pulp, it has a tough and fold-resistant texture, and a rustic and natural feel, making it suitable for environmentally friendly packaging and retro style design.

The surface is coated with gold or silver paint or covered with metal film, which has a dazzling luster and is often used in gift boxes, greeting cards and other scenes that show luxurious texture.

Produced using special techniques or raw materials, it has unique texture, rich colors, and delicate texture, providing more creative possibilities for design.

The paper is white, smooth, crisp and thick, and has strong adaptability to printing. It is a commonly used basic material for making business cards, leaflets, packaging boxes, etc.

By high-temperature embossing of metal foil, the paper is given a striking metallic luster, enhancing its visual quality.

Using molds to print out a three-dimensional relief effect gives flat materials a vivid sense of touch and layering, enhancing visual tension.

Display boxes are widely used in retail counters, exhibitions, and promotional setups. They're designed to catch the eye and present your product clearly and accessibly, encouraging impulse buys and engagement.

At Ecofold, we design display boxes to highlight your branding up close. With customizable shapes and vibrant prints, they turn product placement into a strategic brand interaction—driving recognition right where decisions are made.

View display box solutions for different products and fields and get artistic inspiration.

Display boxes are designed to attract attention at first glance. Their eye-catching presentation increases product visibility, encouraging impulse purchases at the point of sale.

Whether you need bold graphics or minimalistic elegance, display boxes can be fully customized. They provide a flexible canvas to reflect your brand’s unique identity.

Ideal for cosmetics, snacks, or small electronics, display boxes make products accessible and enticing. They are a practical solution for maximizing shelf impact in competitive retail spaces.

Ecofold packaging helps your brand grow

Display box is also called PDQ “pretty darn quick” or “product displayed quickly”.

It is mostly used in supermarkets, retail stores and other places. In addition to displaying the products placed in the display box, the display box can also promote the brand again, attract customers’ attention and increase customers’ purchasing power through the patterns printed on the display box.

Hello, the display box is not folded when it is shipped from the factory. Because of the safety during transportation, the space occupied during transportation and the freight cost. The folding box shipped from the factory is not folded, and stuff needs to be folded when the product is displayed.

First of all, corrugated material is an environmentally friendly material that is recyclable, and chevron board is a plastic that is difficult to recycle. Secondly, corrugated paper can be folded into various shapes by folding, cutting, and other methods. However, due to the problem of hardness, chevron board is more suitable for flat display, and there will be fewer structural changes. At the same time, combined with the actual situation of the brand, the display box made of corrugated is very suitable for short-term promotion and low-cost display.

Hello. If you want to increase the hardness of the overall display box, we can start by increasing the weight of the cardboard, which can increase the hardness without affecting the overall folding difficulty.

The special thing about this display box is that it is already filled with products when it is transported. When the product reaches the retail supermarket, you only need to tear off the upper part along the line on the side, and the lower part of the packaging box will become a simple display box. This not only meets the requirements of protecting the safety of the product, but also has the function of a display box.

This box is more functional than an ordinary folding box. It can be used as a shipping box for the product and can be transformed into a display box after transportation. Its printed pattern can achieve the maximum publicity effect, which is very advantageous.

Yes. You can send us the display method, the size of the displayed products, and the number of displayed products. We will customize it for you.

The structural design of the display box will directly affect the consumer’s experience and perception. So we need to consider the shape, size, opening method, internal structure, layering, interactivity, etc. of the overall display box. For example, whether our opening method is convenient for consumers to take it directly. For example, whether our display method can effectively display the advantages and details of the product, etc. We will focus on the consumer’s perspective to transform passive display into active attraction of consumers. Provide each brand with the best solution to combine their products.

The difference between display boxes and other packaging boxes is that they can be roughly divided into floor-standing and booth-style. Booth-style display boxes are usually small in size and can be produced by general width printing machines. But if it is a large floor-standing display cabinet, it will be limited by materials, production equipment, etc. The standard base paper width is usually 1.1-2.5 meters, and super-large display boxes may need to consider splicing and other processes. The size restrictions of customized display boxes mainly depend on the material specifications and production equipment capabilities. Large floor-standing display boxes need to focus on solving structural stability and transportation problems.

The design of the display box can be integrated into the brand’s concept and story through printing and structural design. For example, Lego’s limited edition display box uses the splicing method of building blocks. This forms a strong link with the brand. For example, the display box of Starbucks’ holiday cup adds the green color of its logo, which strengthens the associative power of the brand’s color.

Contact Info.