Nail clip auto bottom box

Convenient and practical plug-in lid box, your ideal packaging choice

This tuck end box is the most common box type. It achieves efficient packaging with a simple design. It is made of high-quality white cardboard, which is crisp and durable, and can withstand a certain weight and pressure to ensure the safe arrival of items during transportation and storage.

The tuck end box design is extremely exquisite, and it is easy and convenient to open and close. Just gently insert or pull out the tuck end box to complete the sealing and opening actions, without the need for complex tools or additional accessories, which greatly improves packaging efficiency, especially suitable for fast-paced production and logistics scenarios.

Related Products

Customized Process Options

spot UV

Apply UV-curing coating to local areas of printed matter to create a special effect of bright protrusions, thus achieving precise highlighting of the visual focus.

Lamination

A layer of transparent plastic film is covered on the surface of the paper, which is divided into glossy film and matte film, which can enhance the waterproof and wear resistance and improve the overall texture.

UV coating

Through ultraviolet light instant curing technology, a transparent protective layer is formed on the surface of the material, which has both high gloss and scratch resistance, extending the service life of the product.

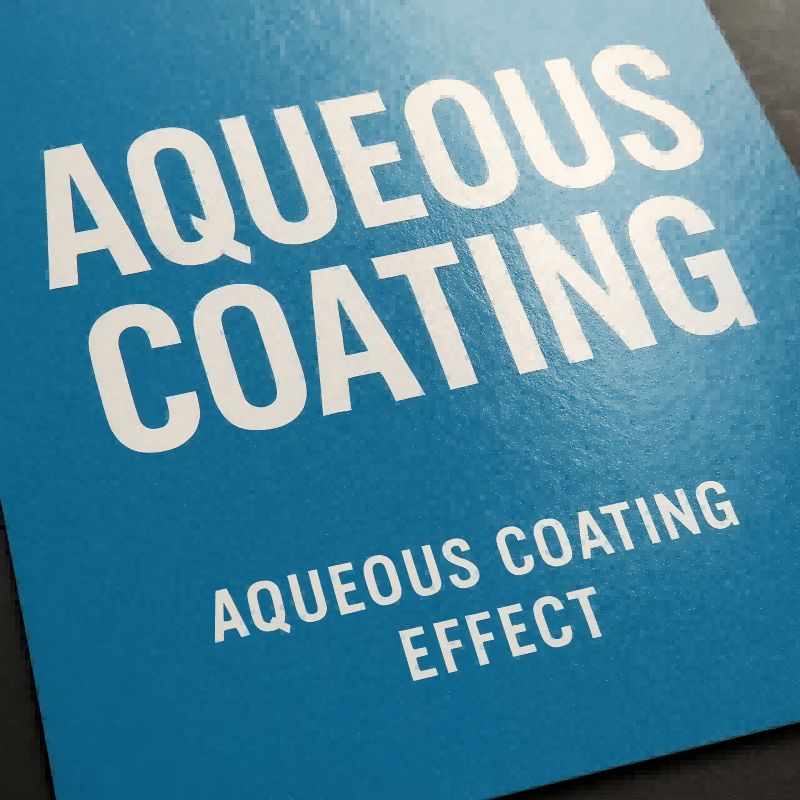

aqueous coating

Environmentally friendly, water-based paint that is safe and non-toxic and can give materials a soft matte or high-gloss surface effect.

Corrugated

It is made of corrugated core paper and surface paper, has good cushioning and shock resistance, and is an economical material commonly used in the packaging field.

Kraft paper

Made of wood pulp, it has a tough and fold-resistant texture, and a rustic and natural feel, making it suitable for environmentally friendly packaging and retro style design.

Silver card paper

The surface is coated with gold or silver paint or covered with metal film, which has a dazzling luster and is often used in gift boxes, greeting cards and other scenes that show luxurious texture.

Specialty Paper

Produced using special techniques or raw materials, it has unique texture, rich colors, and delicate texture, providing more creative possibilities for design.

White cardboard

The paper is white, smooth, crisp and thick, and has strong adaptability to printing. It is a commonly used basic material for making business cards, leaflets, packaging boxes, etc.

hotstamping gold foil

By high-temperature embossing of metal foil, the paper is given a striking metallic luster, enhancing its visual quality.

logo debossing/embossing

Using molds to print out a three-dimensional relief effect gives flat materials a vivid sense of touch and layering, enhancing visual tension.

Inserts

Natural Kraft Paperboard Insert

Folding Carton Box Divider Inserts

Natural Kraft Corrugated Insert

Corrugated Box Divider Inserts

FAQ

Why do some factories say they can produce auto bottom boxes, but some printing factories cannot?

Because the bottom of the auto bottom box needs to be pre-coated with glue. There are certain requirements for the factory’s automation equipment and technology. The bottom cover of the auto bottom box needs to be precisely coated with glue to ensure the firmness and sealing of the bottom cover, so there are also certain requirements for the skills of the personnel who operate the machine. It is necessary to have professional and skilled technical workers who can skillfully change the molds of various sizes of packaging boxes and accurately complete the production process of the auto bottom box.

Will the auto bottom box be more expensive than ordinary boxes?

Yes! The cost will increase appropriately. Because in the box gluing process, the box gluing area will be larger than that of ordinary boxes. The difficulty of gluing boxes and the time for mold adjustment are both greater than those of ordinary boxes. However, for factories that mass-produce auto bottom boxes, there are still certain advantages through years of production experience and optimization of production processes.

This can control labor costs and time costs very well for brands that pack a certain size of products in large quantities.