Elegant Presentation Matters

Sleeves and cards offer a sleek way to elevate product packaging. They provide a refined finish while giving space for branding, promotions, or messaging.

Showcase your products with minimal packaging. Sleeves and cards cut down on material but deliver maximum brand impact and sustainable style.

Choose from our library of custom sleeve&card curated from popular demand.

Apply UV-curing coating to local areas of printed matter to create a special effect of bright protrusions, thus achieving precise highlighting of the visual focus.

A layer of transparent plastic film is covered on the surface of the paper, which is divided into glossy film and matte film, which can enhance the waterproof and wear resistance and improve the overall texture.

Through ultraviolet light instant curing technology, a transparent protective layer is formed on the surface of the material, which has both high gloss and scratch resistance, extending the service life of the product.

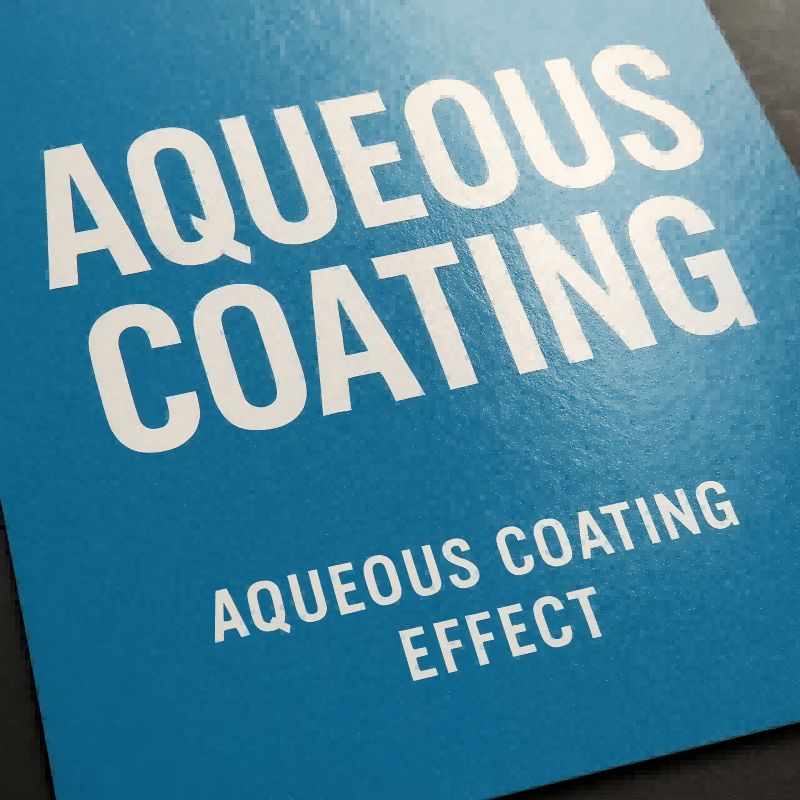

Environmentally friendly, water-based paint that is safe and non-toxic and can give materials a soft matte or high-gloss surface effect.

It is made of corrugated core paper and surface paper, has good cushioning and shock resistance, and is an economical material commonly used in the packaging field.

Made of wood pulp, it has a tough and fold-resistant texture, and a rustic and natural feel, making it suitable for environmentally friendly packaging and retro style design.

The surface is coated with gold or silver paint or covered with metal film, which has a dazzling luster and is often used in gift boxes, greeting cards and other scenes that show luxurious texture.

Produced using special techniques or raw materials, it has unique texture, rich colors, and delicate texture, providing more creative possibilities for design.

The paper is white, smooth, crisp and thick, and has strong adaptability to printing. It is a commonly used basic material for making business cards, leaflets, packaging boxes, etc.

By high-temperature embossing of metal foil, the paper is given a striking metallic luster, enhancing its visual quality.

Using molds to print out a three-dimensional relief effect gives flat materials a vivid sense of touch and layering, enhancing visual tension.

Sleeves and insert cards are commonly used for socks, cosmetics, and stationery. They keep products organized while adding a premium, thoughtful feel—ideal for minimalist or eco-conscious packaging concepts.

We use sleeves and cards to create subtle but powerful branding opportunities. Printed with your story, mission, or care instructions, they turn your packaging into a curated brand experience customers remember.

View sleeve&card solutions for different products and fields and get artistic inspiration.

Sleeves and cards offer a sleek way to elevate product packaging. They provide a refined finish while giving space for branding, promotions, or messaging.

Easily adapted to fit gift boxes, product packaging, or event invitations, sleeves and cards add a sophisticated touch without requiring bulky materials.

Perfect for gift sets, cosmetics, and stationery, sleeves and cards enhance perceived value. They turn a simple product into a beautifully packaged experience.

Ecofold packaging helps your brand grow

Yes, our production equipment meets the production process of blister-coating paper cards. We also produce a large number of blister paper cards to meet different market needs.

Yes, our Sombrero Hang Hole is shaped like the brim of a wide-brimmed hat to prevent paper cards from sliding off the shelf. The diameter is usually 4.76mm (3/16 inch) and is suitable for North American standard shelf hooks. OSHA Hang Hole

In accordance with the Occupational Safety and Health Administration (OSHA) requirements for workplace safety in the United States, the hole size is usually 4.76mm (3/16 inch) and is compatible with standard hooks. Sufficient material thickness must be reserved at the edge of the hole (such as the backing card thickness ≥ 250g/m²) to avoid tearing.

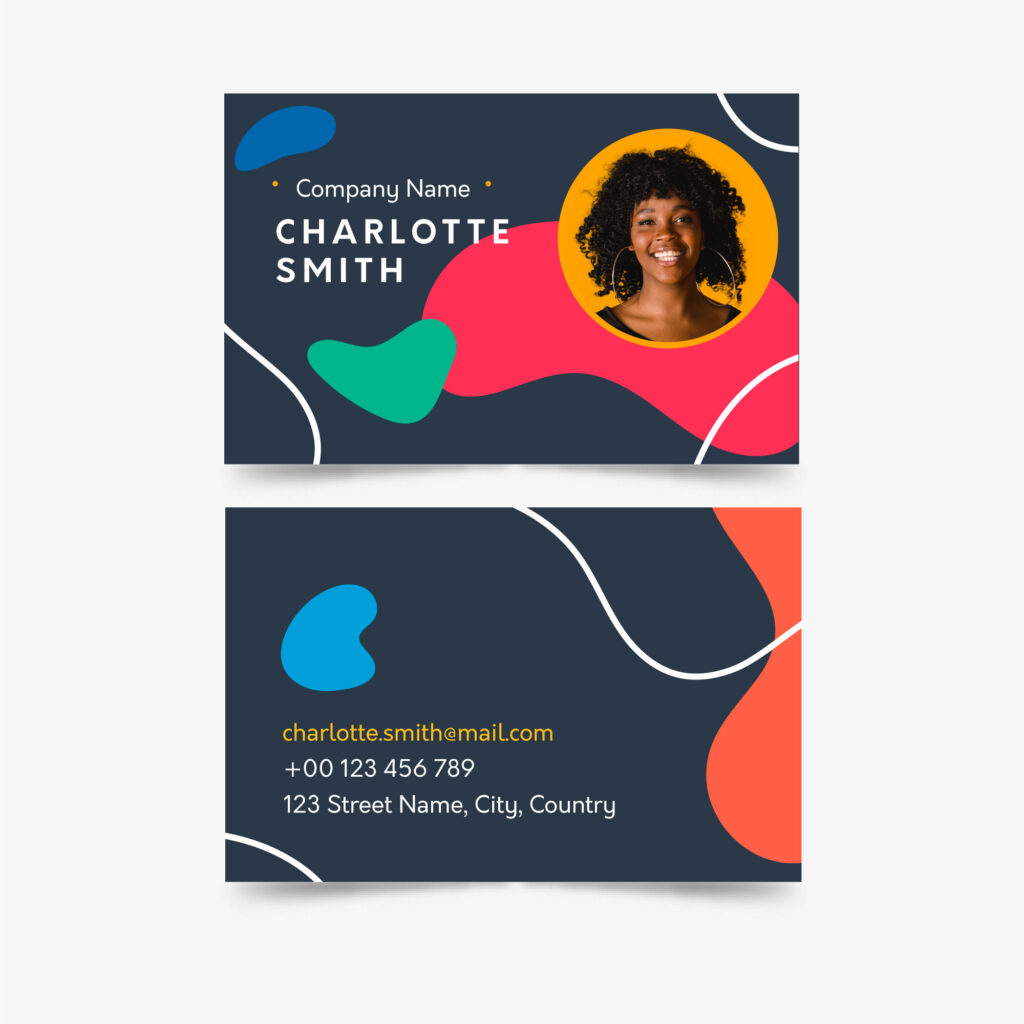

Yes, we can print on both sides of a single sheet of paper, or mount two sheets of paper with the printed sides facing outwards to achieve a pattern on both sides of the paper card.

Yes, we can cover the paper card with a laser film to help the paper card achieve a laser effect.

Hello, yes. We will configure suitable envelopes according to the customized greeting cards, invitations, etc.

Yes. We are committed to realizing various design ideas of customers. Origami cards can meet the needs of multiple scenarios such as publicity, interaction, and portability through structural innovation. We are very happy to try innovation!

There is no minimum order quantity for this product. Because we consider the range of people for business meetings and wedding banquets, we have launched a no MOQ service for this product.

Yes, after receiving it, you only need to unfold the product into a three-dimensional shape and it can be put into use immediately.

The application scenarios of paper waist seals are very wide. It can be seen in catering, fabrics, retail and other aspects. For example, waist seals are used on the outside of takeaway packaging boxes and bread boxes for re-fixing. For example, socks, soft blankets, etc. will also use sleeves for soft fixation. At the same time, the insulation sleeve on the outside of coffee cups that we can see everywhere is also a kind of sleeve.

The biggest advantage of paper sleeves is that they can take into account many functions. In terms of food, it can not only play the role of reinforcing lunch boxes, but also play the role of heat insulation when consumers take them. At the same time, the printing on it helps the brand achieve the function of product promotion.

The sleeve material can be changed directly. We can choose the material of paper according to the characteristics of the brand, such as litchi leather, velvet leather, etc. We can also change the printing process of the brand logo, such as hot stamping, hot silver, concave and convex, etc. As a product that consumers directly contact, the sleeve of the room card can help the brand improve the consumer experience.

Of course, grooves can be added inside to help the room card be better fixed inside, which can be flexibly changed.

This is determined by the shape of the product being covered. For example, if the product is a rectangular block, a normal style is used. If the product is wide at the top and narrow at the bottom like a lunch box, a trapezoidal style is more suitable. This ensures that the waist seal and the product fit better.

Of course. We can customize it according to your requirements and produce your sleeve according to the characteristics of the product and the actual situation.

Yes. We will make a size sample before production to ensure that the sleeve reaches the most suitable degree.

If it is just ordinary four-color printing, there is no minimum order quantity. If hot stamping, partial UV and other processes are required, the minimum order quantity will be appropriately increased.

Contact Info.