Our bearing packaging boxes are engineered with precision to meet the rugged demands of industrial supply chains. Bearings are sensitive, high-value components that require structured protection from moisture, dust, and mechanical damage. That’s why we use premium rigid cardboard or corrugated board with reinforced edges to ensure the product remains intact from warehouse to workshop. Each box is custom-fitted to the size and weight of the bearing, minimizing movement and optimizing shelf presence.

The surface can be treated with matte or glossy lamination, while options for UV spot coating or foil stamping elevate the brand’s visual identity. We also offer oil-resistant inner linings or water-resistant coatings for clients who operate in harsh environments. Our in-house team works closely with industrial manufacturers to ensure every structural fold, locking mechanism, and cushioning insert adds to the product’s protection.

From local automotive parts dealers to international bearing brands, our boxes have been widely adopted in heavy machinery, robotics, and transport equipment supply chains. Whether used for shipping, display, or bulk storage, our bearing packaging solution delivers reliability and professionalism in one sleek form.

Customized Process Options

spot UV

Apply UV-curing coating to local areas of printed matter to create a special effect of bright protrusions, thus achieving precise highlighting of the visual focus.

Lamination

A layer of transparent plastic film is covered on the surface of the paper, which is divided into glossy film and matte film, which can enhance the waterproof and wear resistance and improve the overall texture.

UV coating

Through ultraviolet light instant curing technology, a transparent protective layer is formed on the surface of the material, which has both high gloss and scratch resistance, extending the service life of the product.

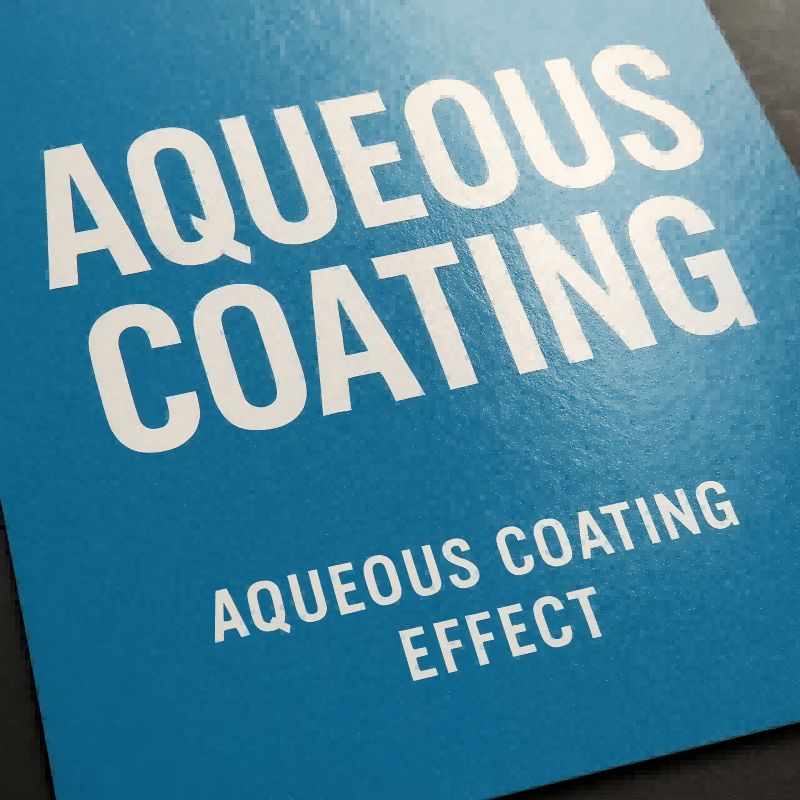

aqueous coating

Environmentally friendly, water-based paint that is safe and non-toxic and can give materials a soft matte or high-gloss surface effect.

Corrugated

It is made of corrugated core paper and surface paper, has good cushioning and shock resistance, and is an economical material commonly used in the packaging field.

Kraft paper

Made of wood pulp, it has a tough and fold-resistant texture, and a rustic and natural feel, making it suitable for environmentally friendly packaging and retro style design.

Silver card paper

The surface is coated with gold or silver paint or covered with metal film, which has a dazzling luster and is often used in gift boxes, greeting cards and other scenes that show luxurious texture.

Specialty Paper

Produced using special techniques or raw materials, it has unique texture, rich colors, and delicate texture, providing more creative possibilities for design.

White cardboard

The paper is white, smooth, crisp and thick, and has strong adaptability to printing. It is a commonly used basic material for making business cards, leaflets, packaging boxes, etc.

hotstamping gold foil

By high-temperature embossing of metal foil, the paper is given a striking metallic luster, enhancing its visual quality.

logo debossing/embossing

Using molds to print out a three-dimensional relief effect gives flat materials a vivid sense of touch and layering, enhancing visual tension.

FAQ

Do you have a full range of die sizes? Do you need to charge die fees for each generation?

We have been engaged in bearing packaging for more than 20 years and have hundreds of die sizes for bearings. Basically, we can meet the needs of customers.

What is the smallest size of paper box you can make?

Our smallest size for fully automatic box gluing is 34*34*12mm.